Dependable Fasteners for Demanding Applications

The A-K Series Insert features a knurled body and a reduced profile head to allow for virtually flush installation. Countersink drilling or dimpling of the parent material can be eliminated. The A-K Series is designed to be used with Grade 5 or Metric Class 8.8/9.8 mating screws.

The A-K Series Insert can be installed using AVK’s ARO brand pneumatic tools or AVK’s SPP™ pneumatic/hydraulic tools. These tools can be located at any position on your assembly line. The A-K Series Insert can be installed either before or after finish.

VIRTUALLY FLUSH INSTALLATIONS are achieved without special hole preparation due to the A-K Series minimal head profile.

VIRTUALLY FLUSH INSTALLATIONS are achieved without special hole preparation due to the A-K Series minimal head profile.

EXCEPTIONAL TORQUE STRENGTH is achieved as the insert’s knurled body expands FILLING THE HOLE.

EXCEPTIONAL TORQUE STRENGTH is achieved as the insert’s knurled body expands FILLING THE HOLE.

QUALITY INSTALLATIONS even in variable thickness materials are assured by AVK’s spin/spin ARO pneumatic tools and our SPP™ pneumatic/hydraulic tools.

QUALITY INSTALLATIONS even in variable thickness materials are assured by AVK’s spin/spin ARO pneumatic tools and our SPP™ pneumatic/hydraulic tools.

SUPERIOR THREAD STRENGTH is provided due to our internal rolled thread manufacturing process.

SUPERIOR THREAD STRENGTH is provided due to our internal rolled thread manufacturing process.

THREADS GAUGE before and after installation due to the increased cross-sectional thickness of the thread area. Thread dilation is prevented.

THREADS GAUGE before and after installation due to the increased cross-sectional thickness of the thread area. Thread dilation is prevented.

INVENTORY REDUCTION is possible because of the A-K Series’ wide grip range capacity. It is 2.5 times greater than conventional rivet nuts.

INVENTORY REDUCTION is possible because of the A-K Series’ wide grip range capacity. It is 2.5 times greater than conventional rivet nuts.

SUPERIOR CORROSION RESISTANCE is provided by our standard zinc/yellow dichromate finish (96 hrs. salt spray to white corrosion). For exceptional corrosion protection we offer a tin/zinc alloy finish.

SUPERIOR CORROSION RESISTANCE is provided by our standard zinc/yellow dichromate finish (96 hrs. salt spray to white corrosion). For exceptional corrosion protection we offer a tin/zinc alloy finish.

AVAILABLE in steel from stock. Additional materials such as aluminum, brass and monel are available by special order. Contact AVK for details.

AVAILABLE in steel from stock. Additional materials such as aluminum, brass and monel are available by special order. Contact AVK for details.

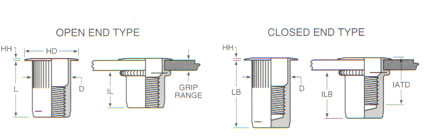

Various A-K Series

Design Types

CLOSED END

Thread area is enclosed eliminating leakage past the threads from either side of the application.